SEEMTEK Electronically Commutated (EC) Centrifugal Fans

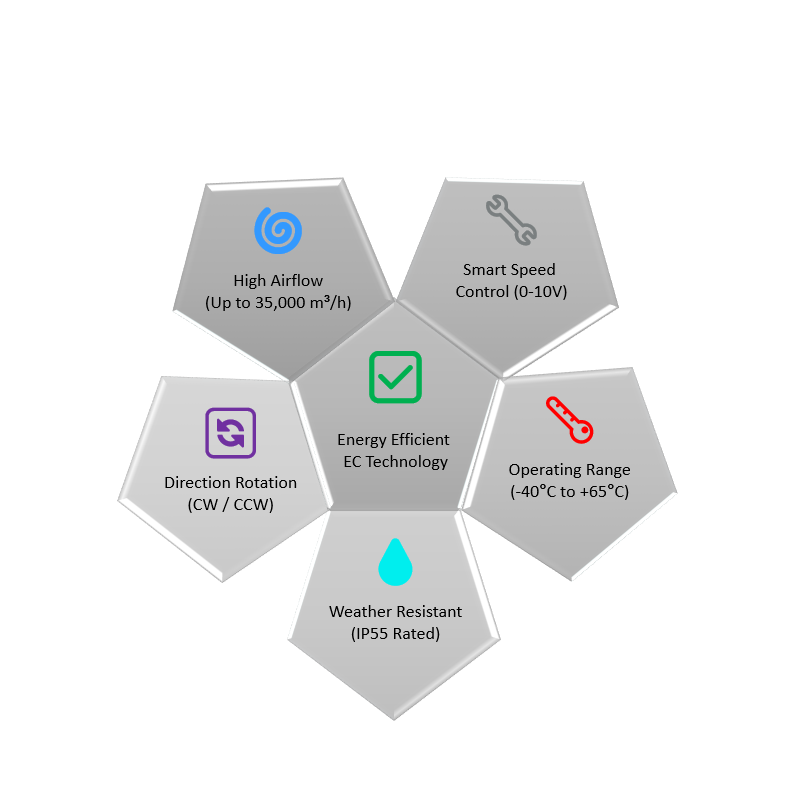

Our Smart EC Fan is a next-generation electronically commuted (EC) centrifugal fan designed to revolutionize HVAC performance in commercial air handling units (AHUs). Combining energy-efficient EC motor technology with intelligent control and monitoring, this fan delivers unmatched performance, reduced operational costs, and future-ready connectivity.

Engineered for seamless integration into both new and existing AHU systems, the Smart EC Fan is the ultimate solution for sustainable building operations.

Download Catalogue

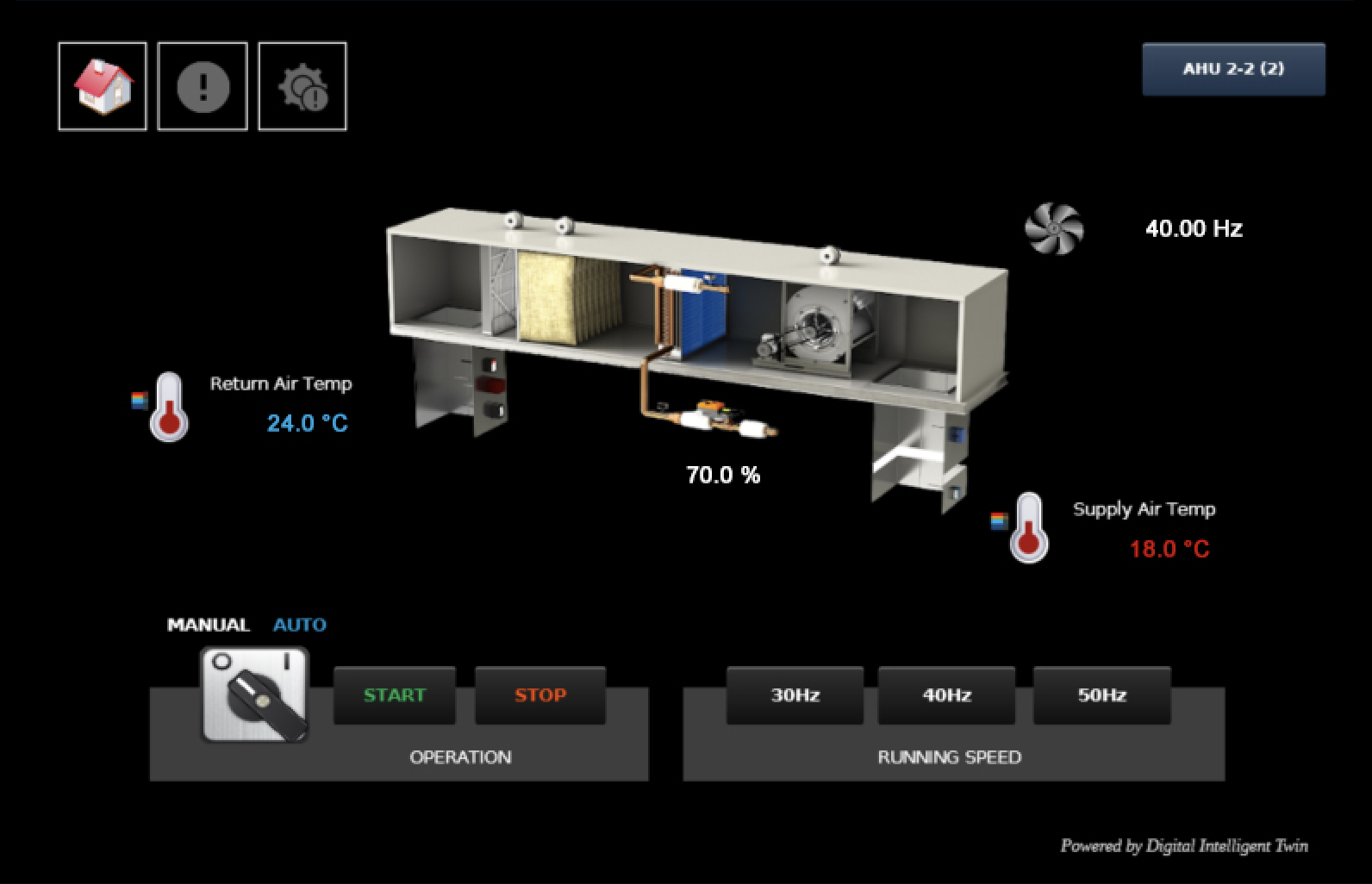

Intelligence at the Core : PLC-Compatible Smart Control

Airflow demand

Static pressure

Temperature sensors

Maintenance alerts

Retrofit-Ready: Unlocking Cost Savings in Existing AHUs

Energy consumption (up to 40–60% savings)

Airflow balance due to modular fan wall configuration

Maintenance efficiency (no belts or pulleys)

Space optimization — smaller footprint and reduced vibration

Why Smart EC Fans Outperform Traditional AHU Fans ?

Built-In Predictive & Preventive O&M Features

Smart EC Fans come equipped with our plc capabilities to help in predictive & Preventive O&M Features. These below features reduce downtime, extend equipment life, and allow facilities teams to switch from reactive to proactive maintenance strategies.

Agent

As an authorized SEEMTEK agent, we deliver premium EC Fan solutions that maximize energy savings and boost HVAC system performance trusted technology for next-level efficiency.